Machine Tool

*SC・JN models include each one set of internal jaws and external jaws as standard. JN models cannot use soft jaws.

*SC-F models include each one set of internal jaws, external jaws and soft jaws as standard. SC-F models are applicable for 5” or smaller sizes.

*When soft jaws are used for SC-F models, the specification such as gripping force and rotation speed must be reduced.

| Model | ① | ||||||

|---|---|---|---|---|---|---|---|

| ② | |||||||

| ③ | - | - | |||||

| Gripping Range (mm) | External Gripping | 2~70 | 3~95 | 3~110 | 3~160 | 4~180 | |

| Internal Gripping | ① | 24~64 | 29~84 | 33~100 | 48~150 | 56~170 | |

| ② | - | 29~84 | 33~100 | 55~150 | 62~170 | ||

| ③ | - | 29~84 | - | 55~150 | 62~170 | ||

| Handle Torque (N・m) | 29.4 | 44.1 | 63.7 | 88.3 | 107.9 | ||

| Max. Static Gripping Force (kN) | 9 | 12 | 15 | 31 | 31 | ||

| Max. Speed (min-1) | 2500 | 2500 | 2500 | 4000 | 3500 | ||

| Moment of Inertia (kg・m2) | 0.001 | 0.004 | 0.009 | 0.030 | 0.060 | ||

| Net Weight (kg) | 1.5 | 3.1 | 4.4 | 8.4 | 12.2 | ||

| Outline Drawing Please click the model to down load. |

2D |  |

|

|

|

|

|

|

|

|

|

|

|||

| - |  |

- |  |

|

|||

| TIF |  |

|

|

|

|

||

|

|

|

|

|

|||

| - |  |

- |  |

|

|||

| DXF |  |

|

|

|

|

||

|

|

|

|

|

|||

| - |  |

- |  |

|

|||

| DWG |  |

|

|

|

|

||

|

|

|

|

|

|||

| - |  |

- |  |

|

|||

| 3D | Parasolid |  |

|

|

|

- | |

| - | - | - |  |

|

|||

| - | - | - | - | - | |||

| STEP |  |

|

|

|

- | ||

| - | - | - |  |

|

|||

| - | - | - | - | - | |||

| Model | ① | ||||||

|---|---|---|---|---|---|---|---|

| ② | - | - | |||||

| ③ | - | - | |||||

| Gripping Range (mm) | External Gripping | 5~220 | 5~260 | 10~300 | 25~315 | 25~360 | |

| Internal Gripping | ① | 62~210 | 70~250 | 86~290 | 107~290 | 113~340 | |

| ② | 70~210 | 80~250 | 90~290 | - | - | ||

| ③ | 70~210 | 80~250 | 90~290 | - | - | ||

| Handle Torque (N・m) | 147.0 | 176.5 | 206.0 | 225.6 | 245.0 | ||

| Max. Static Gripping Force (kN) | 37 | 46 | 55 | 40.5 | 45 | ||

| Max. Speed (min-1) | 2900 | 2500 | 2200 | 1500 | 1500 | ||

| Moment of Inertia (kg・m2) | 0.160 | 0.253 | 0.588 | 0.950 | 1.725 | ||

| Net Weight (kg) | 21.2 | 28 | 41 | 54 | 74 | ||

| Outline Drawing Please click the model to down load. |

2D |  |

|

|

|

|

|

|

|

|

- | - | |||

|

|

|

- | - | |||

| TIF |  |

|

|

|

|

||

|

|

|

- | - | |||

|

|

|

- | - | |||

| DXF |  |

|

|

|

|

||

|

|

|

- | - | |||

|

|

|

- | - | |||

| DWG |  |

|

|

|

|

||

|

|

|

- | - | |||

|

|

|

- | - | |||

| 3D | Parasolid | - | - | - | - | - | |

|

|

|

- | - | |||

| - | - | - | - | - | |||

| STEP | - | - | - | - | - | ||

|

|

|

- | - | |||

| - | - | - | - | - | |||

注)1. ① SC・JN models include each one set of integrated internal hard jaws and integrated external hard jaws as standard. JN models cannot use soft jaws.

2. ②SC-F models includs each one set of internal hard jaws, external hard jaws and integrated soft jaws as standard.

3. When the soft jaws are used for SC-F models, lower the specification of the chuck.

4. JN-T(N) models include each one set of two-piece hard jaws and two-piece soft jaws as standard.

5. ③SC-N and JN-N are CE compliant. The handle is different from others.

Download the instruction manual for CE compatible models here.

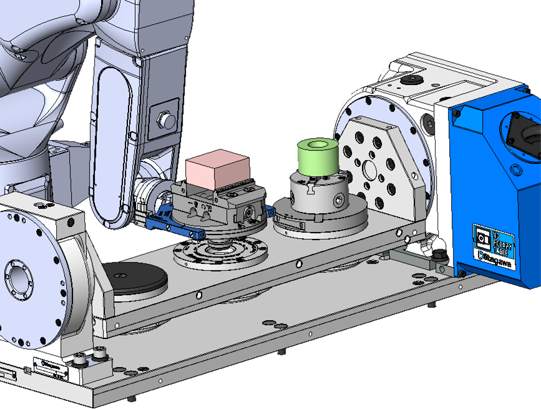

6. The gripping range may be limited due to the NC rotary table model.

Wide variety of world’s standard power chuck

High gripping force & stability to suit various requirements

Necessary item for Quality control and Safety

Standard Manual Chucks suit to a high-mixture of work pieces and low-volume production.

High performance Rotary Cylinder is integral to for the operation of a power chuck and extracts the maximum capability of the chuck.

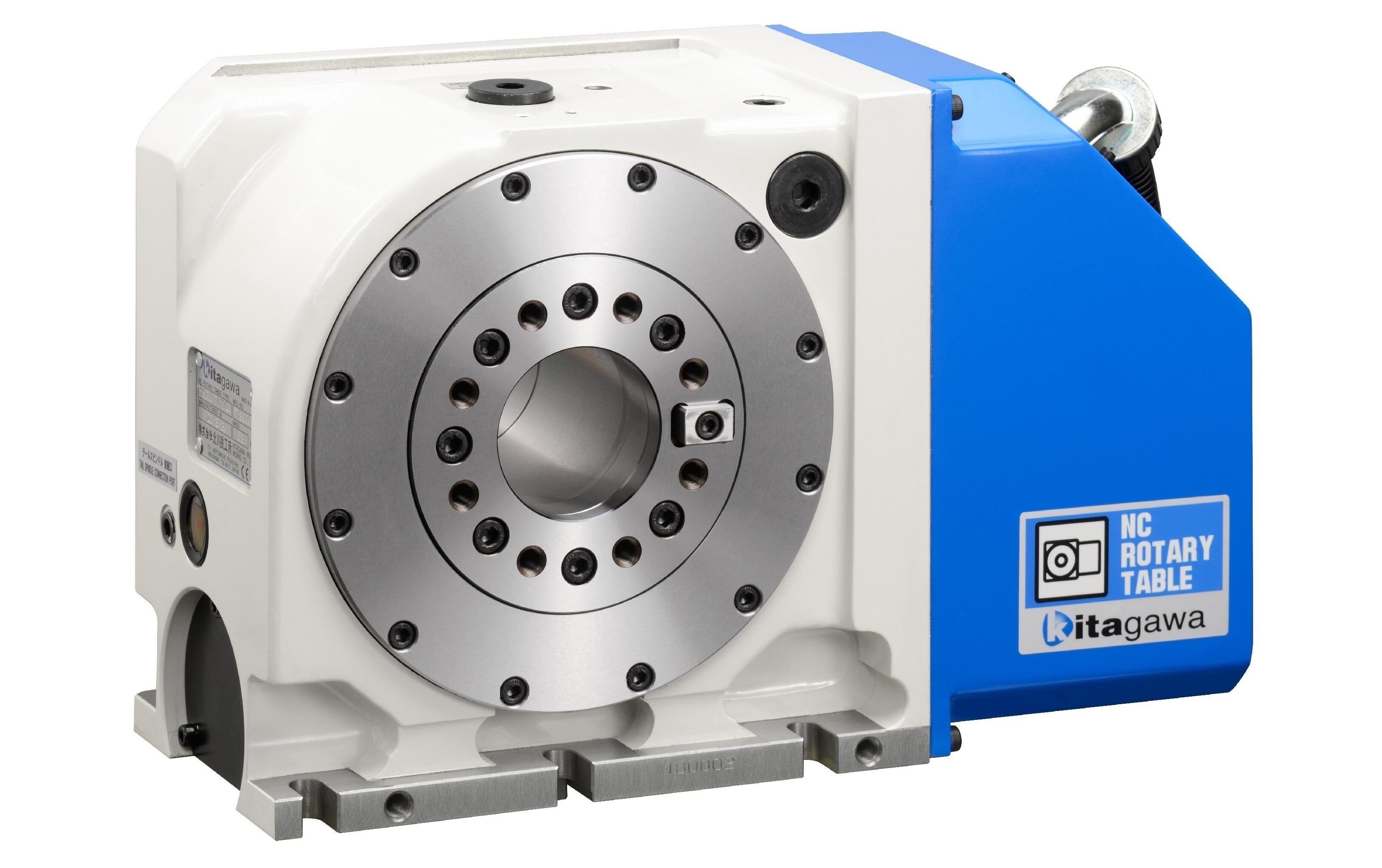

Compact & high accuracy Combination with chuck is available.

Toggle joint mechanism Long jaw stroke

Stationary power chuck with built-in cylinder

Tail stocks, tail spindles, rotary joints, rotary chucks and others

Kitagawa's original grippers with high-quality and high-durability

Strongly support factory automation and unmanned operation

Various catalogues can be downloaded.

Various flyers can be downloaded

Information on discontinued products is posted.