Machine Tool

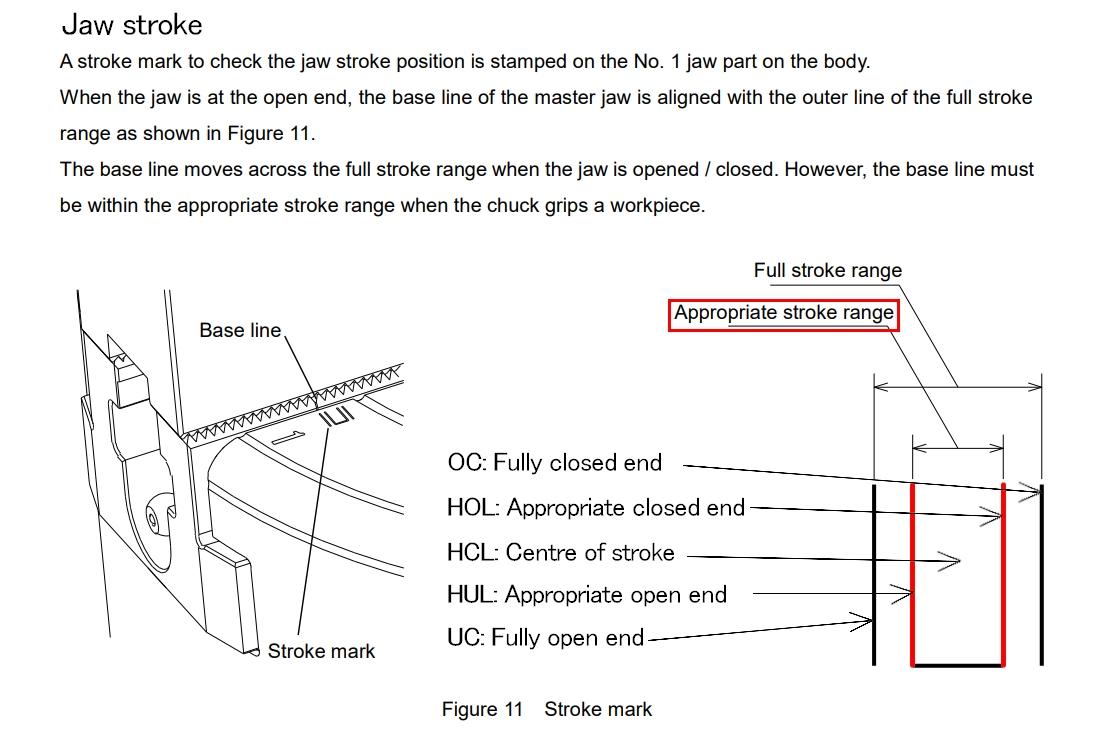

Jaw stroke

Wide variety of world’s standard power chuck

High gripping force & stability to suit various requirements

Necessary item for Quality control and Safety

Standard Manual Chucks suit to a high-mixture of work pieces and low-volume production.

High performance Rotary Cylinder is integral to for the operation of a power chuck and extracts the maximum capability of the chuck.

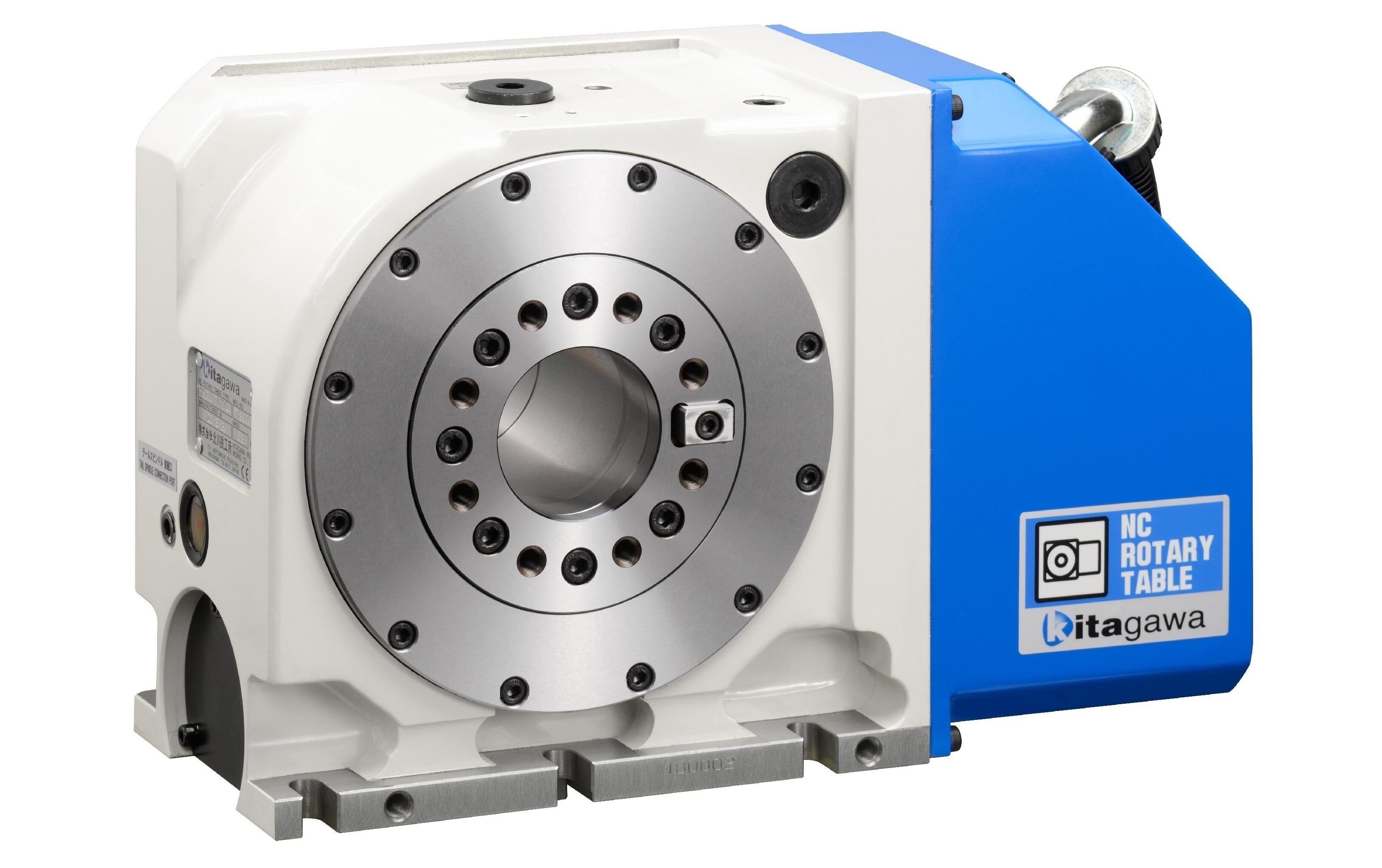

Compact & high accuracy Combination with chuck is available.

Toggle joint mechanism Long jaw stroke

Stationary power chuck with built-in cylinder

Tail stocks, tail spindles, rotary joints, rotary chucks and others

Kitagawa's original grippers with high-quality and high-durability

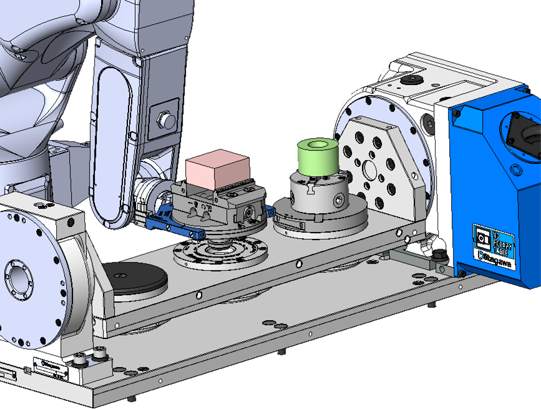

Strongly support factory automation and unmanned operation

Various catalogues can be downloaded.

Various flyers can be downloaded

Information on discontinued products is posted.