Machine Tool

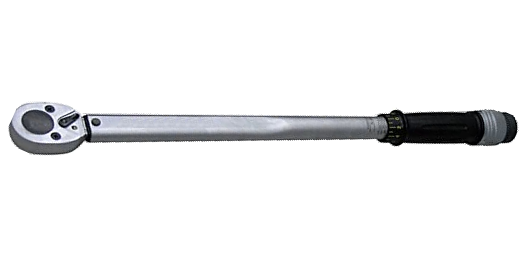

(Note 1) Please prepare a torque wrench and a wrench socket separately.

(Note 2)The value is measured using combination jaws near the centre of the jaw. The value increases as the distance from the centre increases.

| Model |

(N・m) |

(kN) |

(mm) |

(kg) |

|

|---|---|---|---|---|---|

| V75V13C | 100 | 20 | 130 | 3.0 | |

| V75V17C | 100 | 20 | 170 | 3.6 |

*The mass includes a set of jaws.

| Model |

|

|

|

|||

|---|---|---|---|---|---|---|

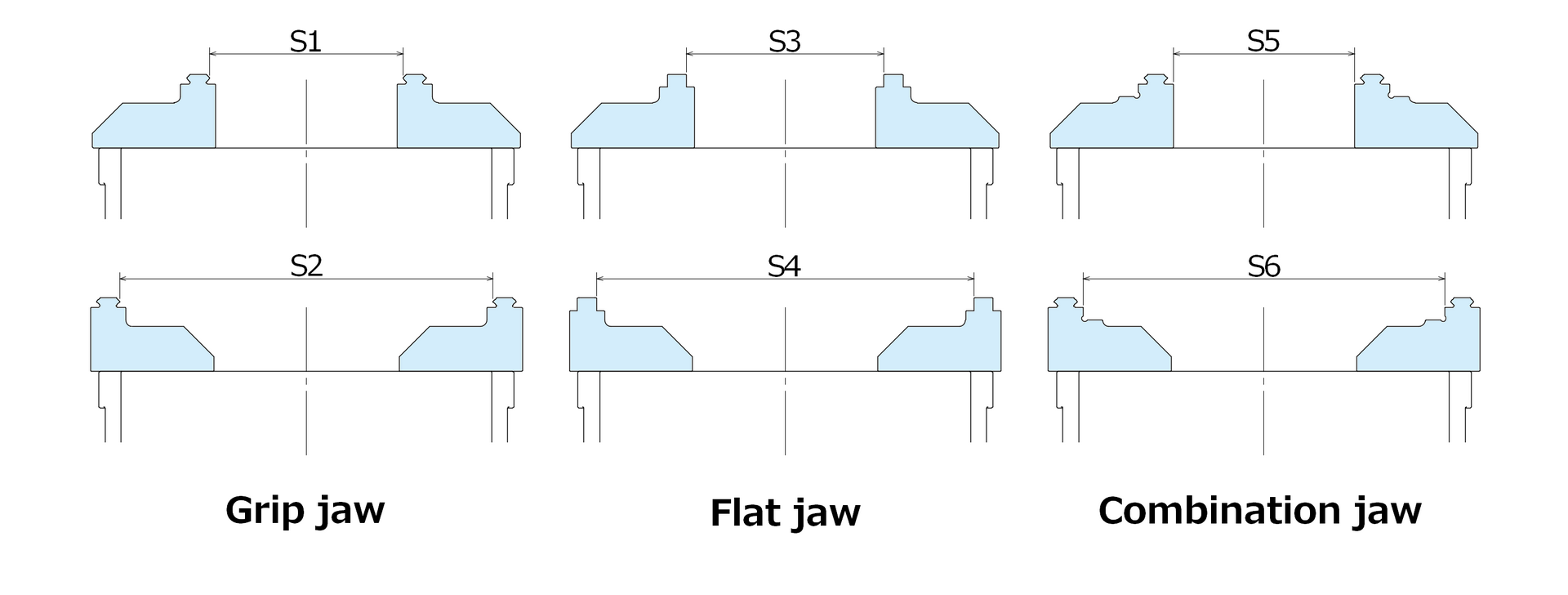

| S1 (mm) | S2 (mm) | S3 (mm) | S4 (mm) | S5 (mm) | S6 (mm) | |

| V75V13C | 3.8 - 60.6 | 59 - 117 | 5 - 61.8 | 60.2 - 118.2 | 0[12] - 56.8 | 55.2 - 113.2 |

| V75V17C | ||||||

Note 1) The jaw stroke of the standard grip jaw is the grip tip position.

Note 2) The jaw stroke of the combination jaw is between flat surfaces. The gripping range at the tip of the grip is the same as the standard grip jaw.

Note 3) The values in [ ] are for when a parallel plate is used.

Refer to the instruction manual for how to use.

|

Grip jaw |

|

2 pcs. / set (expendable) |

|---|---|---|

|

Flat jaw |

|

2 pcs. / set (expendable) |

|

Combination jaw |

|

2 pcs. / set (expendable) |

|

Stripper bolt (1 set included as standard) |

For mounting jaws |

4 pcs. / set (expendable) accessory |

|

Parallel plate |

|

2 pcs. / set |

|

M5x6 |

|

4 pcs. / set |

|

Torque wrench Preset type Setting range: Drive square: 12.7mm |

|

|

|

Torque wrench socket Drive square: 12.7mm Width across flat: 12mm |

|

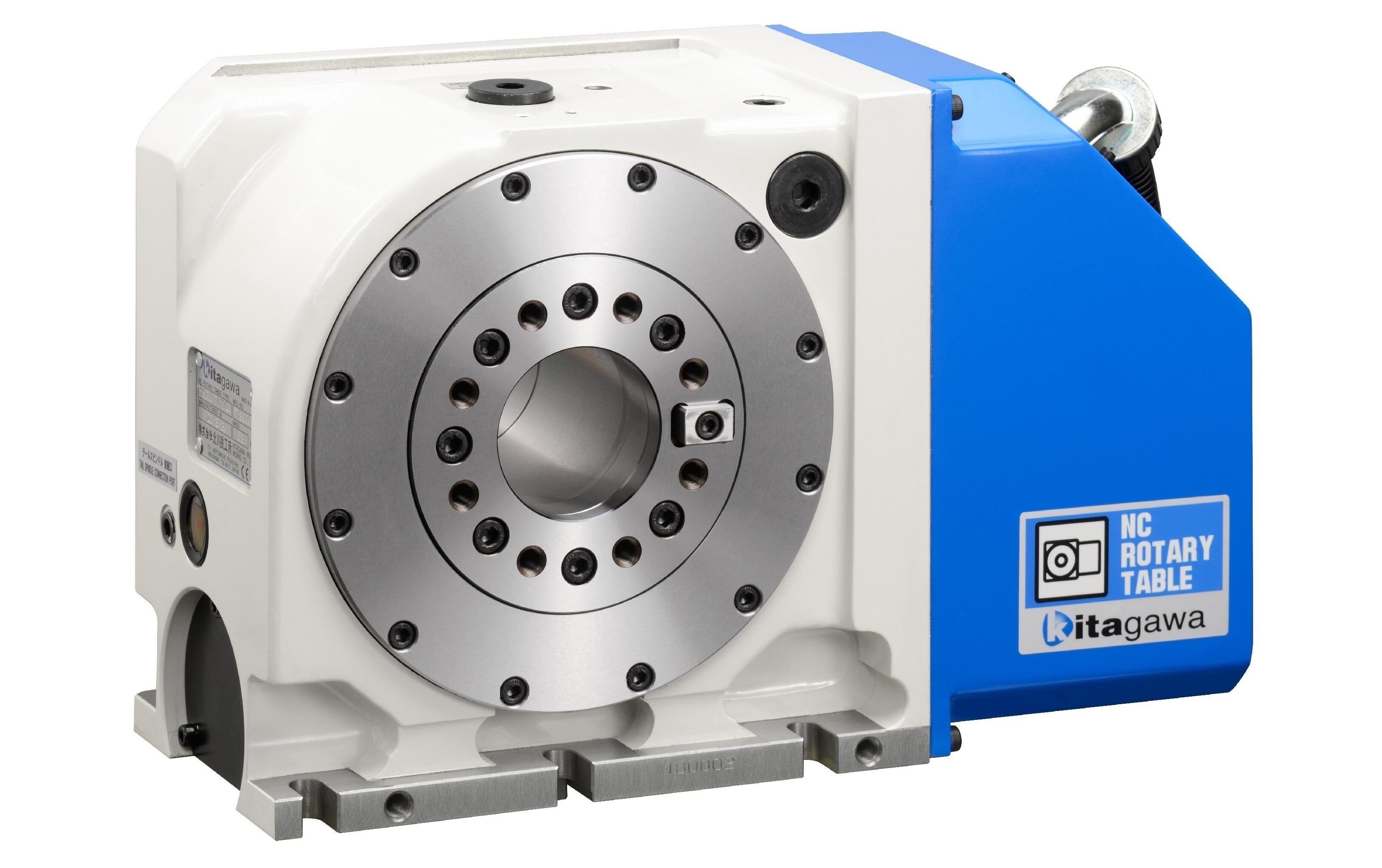

Wide variety of world’s standard power chuck

High gripping force & stability to suit various requirements

Necessary item for Quality control and Safety

Standard Manual Chucks suit to a high-mixture of work pieces and low-volume production.

High performance Rotary Cylinder is integral to for the operation of a power chuck and extracts the maximum capability of the chuck.

Compact & high accuracy Combination with chuck is available.

Toggle joint mechanism Long jaw stroke

Stationary power chuck with built-in cylinder

Tail stocks, tail spindles, rotary joints, rotary chucks and others

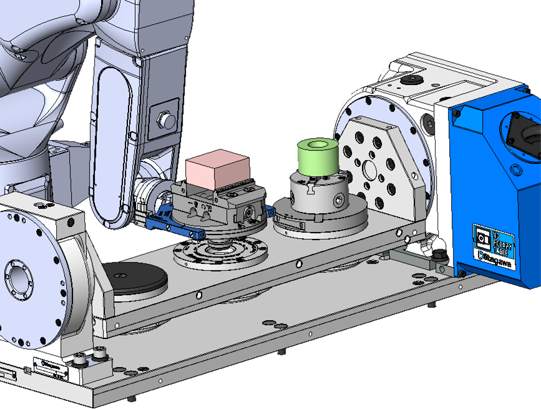

Kitagawa's original grippers with high-quality and high-durability

Strongly support factory automation and unmanned operation

Various catalogues can be downloaded.

Various flyers can be downloaded

Information on discontinued products is posted.